to view content for your location.

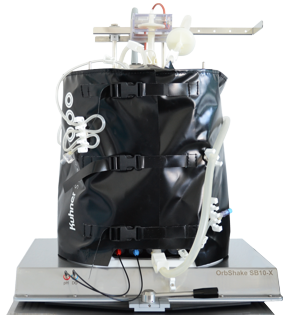

The SB10-X is an orbital shaken benchtop bioreactor

system for the cultivation of human, mammalian and plant cells in a single-use

bag. It consists of six modules (excluding the bag) and has a working volume

from 4 litres up to 12 litres.

The SB10-X can be used in research, process development or as a pilot scale

bioreactor.

Cultivation of human, mammalian and plant cells

Fast, simple set up

Easy scale-up

Online measurement and control of pH and DO

Three different types of single-use bags available

5 year warranty

Single-Use

Scale-Up

GMP

Want to know if the Orbital Shaken Bioreactor (OSB) is suitable for your application?

In the Shaking Technology Hint section, Dr Shaker helps you compare OSB and STR systems, understand the differences between single-use and stainless-steel bioreactors, and identify the best solution for your bioprocess.

Newly developed vessel module with smaller working volumes.

The cylindrical vessel accepts a single-use 3D bag. This bag requires no additional mixing device, enables quick set up times and eliminates elaborate cleaning and sterilising procedures. Various ports are incorporated to allow feeding, inoculation, harvesting and sampling. The standard bag has built-in optical sensors for pH/DO allowing online measurement and control of pH and DO in the medium. Two other bag types are available: a basic single-use bag with no optical sensors and a perfusion bag for ATF and TFF perfusion.

The orbital motion of the SB10-X ensures efficient liquid mixing. It facilitates high oxygen transfer rates with low shear forces. Mechanical stress on the cells is reduced thanks to bubble-free surface gassing with almost no frothing. This motion is particularly suitable for microcarrier cultivation. The SB10-X uses the unique Kuhner direct drive which is very robust and provides accurate control of the orbital speed.

The SB10-X fills a gap in the scale-up chain from commonly used

single-use flasks all the way up to 50 L and 200 L bioreactors. The consistent

hydrodynamics of shaken bioreactors provide reproducible cultivation conditions

throughout the volume range. The culture from the SB10-X can serve as a

preculture for the SB50-X and SB200-X. The SB10-X can also be used

as a pilot scale bioreactor.

The tray module, which is fixed onto the ES-X shaker module, contains integrated heating and the connections for online pH and DO measurement.

Special emphasis has been placed on developing a user-friendly vessel

module. The vessel together with its bag can be easily detached by the user and

carried to the clean bench.

For the

SB10-X, there are two vessel modules available with different working volumes.

The standard module is a 10L-vessel module with a working volume of 4 to 12 L.

The 3L-vessel module has a working volume of 1.5 to 4.5 L and is either available

as an option in addition to the standard SB10-X or customers may purchase the

SB10-X with the 3L-vessel only.

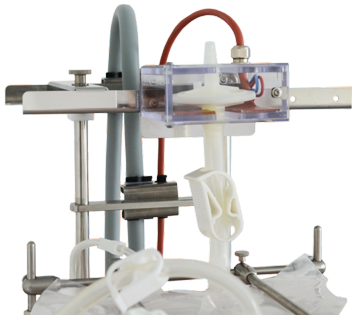

A filter heater for one exhaust filter is placed above the vessel module. The magnetic mounting makes handling the filter heater very simple and allows its location in various places. The filter heater combats water vapour condensation in the outlet air preventing blockages in the membrane

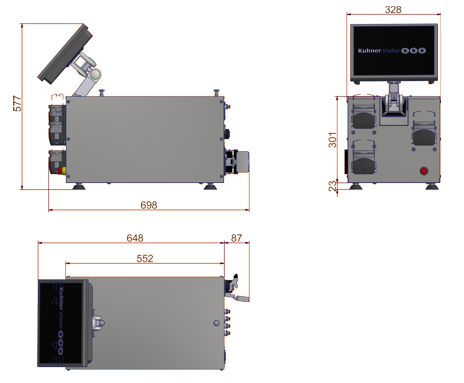

The compact and functional design of the control unit provides easy

handling and monitoring of the bioprocess parameters. The control unit has an integrated

and adjustable 12” touch screen with USB and Ethernet connections. The Kuhner

Insight application software for data recording, calibration, programming and

controlling is user-friendly and 21 CFR Part 11 compliant. Control of pH/DO, medium temperature, shaking

frequency and gas flow rate and mixture is possible.

The control unit incorporates three peristaltic pumps which allow aseptic fluid management. This enables simple regulation of the pH-value, feeding and the transfer of the culture media (scale-up or processing).

The SB10-X control unit has an integrated gas mixing device (FlowCon).

Whether stabilizing the pH with CO2, or preventing

low dissolved oxygen concentrations, the gas mixer meets all user needs. Four

mass flow controllers (N2, O2, CO2 and air or gas

mixture) ensure highly accurate and reproducible gas mixing. An integrated

pressure sensor prevents over pressure in the bioreactor. Step limits can be

freely programmed by the user. Integrated air filters and back pressure valves

ensure interference free and long operating times for the FlowCon.

We subject all our shaking machines to an elaborate final test before delivery and send the test protocols to our customers.

Includes 6 module | - Shaker module ES-X Bioreactor:

- Tray module |

|

|

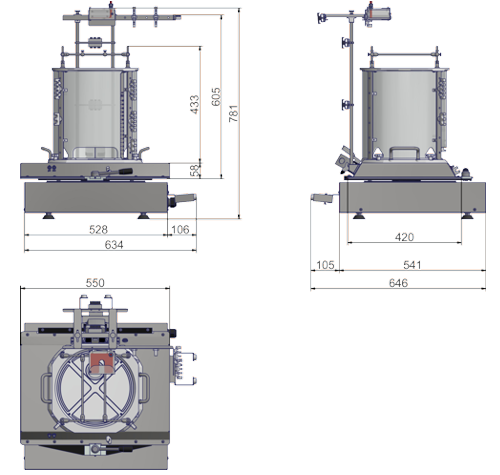

Working volume | 4 L - 12 L |

Total bag volume | approx. 24 L |

Weight | approx. 75 kg without liquid |

Required footprint | 669 mm x 646 mm |

Technical data subject to change | |

Motor |

modified ES-X benchtop shaker |

Shaking diameter | 50 mm (orbital motion) |

Shaking speed | 20 rpm - 140 rpm |

Loading, maximum | 25 kg |

Setting, digital |

1 rpm |

Accuracy, absolute |

± 0.5 rpm |

Active brake |

adjustable |

Ambient temperature | 5°C - 40°C |

Casing |

stainless steel 1.4301 |

102023: | 110 - 120 V / 50-60 Hz |

102024: | 95 - 105 V / 50-60 Hz |

Heating | resistance heater (100 W), |

Temperature max. | 40 °C |

Temperature min. |

approx. ambient temperature (no cooling) |

Temperature accuracy | ± 0.25 °C (at 37 °C) |

Temperature distribution |

8 mm thick aluminum plate provides homogenous temperature distribution

of resistance heater |

pH measurement | principle: optical chemosensor, |

Range | pH 5.5 – pH 8.5 |

Accuracy (chemosensor) | ± pH 0.05 at pH 7 with one point calibration |

Drift |

< pH 0.005 per day |

Temperature range | up to 50 °C |

DO measurement | principle: optical chemosensor, |

Range | 0 % – 100 % DO |

Accuracy (chemosensor) | ± 0.1 % O2 at 20.9 % O2 |

Accuracy (system) | ± 10 % DO |

Drift |

< 0.015 % O2 per day |

Temperature range |

up to 50 °C |

Capacity | 1 exhaust filter |

Casing | polycarbonate |

Heating | resistance heater (6 W) |

Max. temperature | approx. 40 °C at 23 °C ambient temperature |

Control |

orange LED light

indicates that filter heater is active and working |

| (SMX76011) |

Weight | approx. 30 kg |

Required footprint | 698 mm x 328 mm |

Casing | Stainless steel 1.4301 |

Interface | 2 x CAN-Bus |

Display | 12.1’’ screen (resistive) |

Resolution | 1024 x 768 |

Cooling | passive with no fan |

Main memory | 2 GB (1.6 GB usable) |

Interfaces | 4 x USB, 2 x RS 232, 2 x LAN, 1 x VGA |

| Kuhner Insight application software |

Monitoring |

pH & DO, shaking

speed, temperature, gas flow and mixture, pressure |

Calibration | pre-calibrated sensors in bag |

Recalibration | one point recalibration is possible |

Applicable | Win 7 & 10 |

GMP |

21 CFR Part 11 compliant |

| 3 peristaltic pumps |

Type | Watson-Marlow 313 VBM/D |

Rollers | 3 |

Power | 70 W |

Maximum Speed | 100 rpm |

Tube | 1.6 mm wall thickness |

Delivery Pressure | max. 2bar |

Tube ID (mm) | Flow rates (mL/min) at 100 rpm |

0.5 | 3.4 |

0.8 | 7 |

1.6 | 27 |

3.2 | 100 |

4.8 | 220 |

6.4 | 360 |

8 | 500 |

Number of mass flow controllers | 4 |

Ambient conditions |

5 °C – 40 °C, max. 85 %rH |

Input | up to 4 gases (air, oxygen, nitrogen, carbon dioxide) |

Output | 1 (tube fitting

optimal for tubing 9 x 1 mm)

air: 0.1 L min-1 – 1.99 L min-1

|

Pressure measurement | gas output: pressure sensor DELOS SI (Jumo), |

Differential pressure | 0 mbar – 100 mbar (programmable) |

Gas filter | integrated, prevents blocking of mass flow controllers |

Technical data subject to change

With the 3L-vessel module, users can now perform cell cultivations in smaller working volumes ranging from 1.5 to 4.5 L. The 3L-vessel simply replaces the standard 10L-vessel on the SB10‑X shaking table. The smaller module is offered as an option in addition to the standard SB10‑X, or users can purchase the shaking bioreactor with just the 3L-vessel.

A retrofit kit is also available for current users of the SB10-X bioreactor who could benefit from the smaller module. The kit includes additional components for the tray module, a 3L-vessel module, and the software and firmware updates. The shaking diameter should be adjusted to 25 mm. Suitable 3L-single-use cultivation bags are ready for purchase.

We are happy to provide data on kLa, mixing time, volumetric power input, heating time, and evaporation rate to help our customers scale up their bioprocesses.

IQ-OQ (Installation Qualification and Operation Qualification) is an equipment qualification according to GMP procedure. Kuhner offers this service which can also be carried out at the customer’s premises.

Kuhner offers three different single-use bag types to

meet all user needs. Each pack contains three bags.

These gamma-irradiated bags for the Kuhner shaken bioreactor require no

additional mixing device, enable quick set up times and eliminate elaborate

cleaning and sterilising procedures. All bags have a working volume from 4

litres up to 12 litres. Various ports are incorporated to allow feeding,

inoculation, harvesting and sampling.

The standard bag (SMX760001) has built in optical sensors for pH and DO which

allow non-invasive online measurement and control of pH and DO. This standard

bag is suitable for ATF perfusion.

The basic single-use bag (SMX760002) is the same as the standard bag, but has

no optical sensors.

The perfusion bag (SMX760003) has two exhaust filters and is equipped with

additional tubes and ports for TFF perfusion. ATF perfusion is also possible.

Order number | Description |

|---|---|

105327 | 3 x standard single-use bags for SB10-X with optical chemosensors for pH/DO and tubes |

105328 | 3 x basic single-use bags for SB10-X |

105329 | 3 x perfusion single-use bags for SB10-X with 2 exhaust filters, optical chemosensors for pH/DO and additional tubes |

This light protection jacket is easily placed over the vessel module. It protects light sensitive media or products from UV and artificial light as well as daylight.

Order number | Description |

|---|---|

106119 | Light protection jacket |

Order number | Description |

|---|---|

106120 | Red overpressure valve, OD 9mm |

106025 |

2 glass fibers for pH/DO probes, length 40cm |

MagFix is a set of 8 magnetic tube holders to help secure and guide all

the tubing. It consists of 6 units for tubing OD 6mm/11mm and 2 units for

tubing OD 15mm. The tubing fits easily into the slots on each unit. These

magnetised holders can be attached to various steel surfaces on the vessel

module, cable management module and shaker module of the SB10-X. The magnets on

these units are so strong that they are also effective through the light

protection jacket.

Order number | Description |

|---|---|

107621 | MagFix |

Two additional interfaces, EMI-60 and NET-60, are available as options.

EMI-60:

The EMI-60 has several interfaces: two analogue outputs and two individually configurable alarm relays.

NET-60:

NET-60 allows the machine to be connected to almost all conventional

Bus-systems and to OPC servers.

Characterisation of SB10-X single-use bioreactor

Distribution and mixing times of microcarriers

New Orbital Single Use Bioreactor

Orbital Mixing as an Alternative to Stirred-Tank Bioreactors

Characterization of orbitally shaken single-use bioreactors

Baculovirus-based r-protein production in orbitally SUB

Cultivation of entomopathogenic fungi in orbitally shaken bioreactors

Scale Up from shake flask to orbital shaken bioreactors

Orbital Shaken Bioreactors

The Scale Up Fast Track

Real-time monitoring and comparative analysis for density and viability of CHO-M cell in SB10-X shaking bioreactor using the C-Netics

Flexible production of an Fc-fusion protein

Demonstration of Scalable AAV Vector Production in Kuhner SB10-X Orbital Shaken Bioreactor Using a Novel Human Amniotic Epithelial-Derived HAT Cell Line

In our Science Room, we provide general information and data on cultivation processes in Shaken bioreactors.

The SB10-X is an orbital shaken benchtop bioreactor system for the cultivation of human, mammalian and plant cells in a single-use bag. It has a working volume from 4 litres up to 12 litres. Also perfusion processes can be easily realized (ATF / TFF).

The SB10-X can be used in research, process development or as a pilot scale bioreactor

In this video, you can see how to unpack the single-use bag before installing it into the SB10-X.

In this video, you can see how to install the single-use bag into the SB10-X.

With the 3L-vessel module, users can now perform cell cultivations in smaller working volumes ranging from 1.5 to 4.5 L.

The following flyers provide information about

the machines and function-specific solutions.

Kuhner shakers are suitable for the cultivation of microbial, plant, human and animal cell cultures. Find more information about the different application areas and suitable product recommendations for optimal cultivation here.

Adolf Kühner AG (Headquarters)

Dinkelbergstrasse 1

CH-4127 Birsfelden (Basel)

Switzerland

We support our customers in implementation, maintenance and repair of all Kuhner products – efficiently and competently.

For Kuhner, the quality and durability of their shakers and bioreactors have always been the topics with the highest priority. On this account, Kuhner products have also proven their worth worldwide under GMP requirements. Documentation, development and production along the full life cycle of our products are continuously enhanced to match the requirements of 21 CFR and GAMP 5.

Read more

The world's most reliable shaking machines built in-house in Switzerland.