to view content for your location.

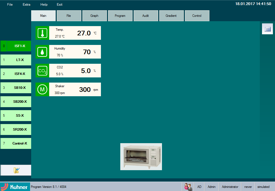

The Kuhner Insight software is a user-friendly interface for capturing data and controlling system parameters on Kuhner equipment. Insight also allows the user to programmatically control these parameters and calibrate their values as needed. Simultaneous control and recording of process parameters is possible in up to 8x shakers or orbitally shaken bioreactors (OSB).

The Kuhner Insight Software is the universal tool for any experiment. In connection with an intuitive interface, the software continuously records and saves all relevant process parameters, including: shaker speed, temperature, humidity, and CO2 concentration. Insight will also capture information from measurements of dissolved oxygen (DO) and pH with our orbitally shaken bioreactors (OSB). All interactions with the shaker machine (e.g. user log in or setpoint changes) are also captured.

To easily monitor your experiment, all process parameters can be displayed and printed a in formattable diagram. Setpoints for the different process parameters can either be defined in a program, which is automatically executed, or changed manually through the control panels (e.g. shaking speed and temperature).

With Kuhner Insight, you define your own user management policy to fit your needs. The multi-user interface of the software provides access for up to 255 users in customizable groups with different privileges.

Control

Recording

Multi user interface

Connectivity

GMP features

Kuhner Insight allows for the calibration of the shakers and OSB, as well as the generation of corresponding controller certificates, which is especially helpful for IQ/OQ purposes. For convenience, it is possible to connect Kuhner Insight to the machine locally with a USB/CAN interface or remotely with a CAN/Ethernet gateway. The Kuhner Insight software can also be operated on a fully integrated touchscreen panel, which is especially useful for application in a GMP environment.

The software covers the important requirements demanded when working under the rules of ISO-9001 or GMP/GLP. Technical controls for 21 CFR Part 11 compliance are also built into the software. The Kuhner Insight Software allows the user to programmatically automate batch processes and is equipped with an autosave function that allows to the user to continuously record batch data. The audit log, which documents every manipulation made to the system, will also capture any alarms that are trigged throughout the process. Any alarms that may be triggered during a process will also require acknowledgement from the user, ensuring that the users remain fully informed of any deviations encountered during a process.

IQ-OQ (Installation Qualification and Operation Qualification) is an equipment qualification according to GMP procedure. Kuhner offers this service, which can also be carried out at the customer’s premises.

Are you interested in our Kuhner Insight software? Would you like to get a free demo version?

Please contact us at +41 61 319 93 93 or office@kuhner.com

Further Kuhner Technologies: