to view content for your location.

The maintenance-free and long-lasting Kuhner direct drive ensures consistent and reliable shaker performance. It allows the shaking diameter to be changed by the customer quickly and easily at any time. The direct drive offers high shaking frequencies up to 500 rpm (depending on shaking diameter and load). For cultivations in microtiter plates, an optional high-speed version (HS drive) is recommended for faster shaking frequencies up to 1000 rpm (at 3 mm orbit diameter). The direct drive system accepts loads up to 25 kg. For heavy and large cultivation vessels or vessels with baffles, an optional high-performance version (HP drive) with more power is available for loads up to 60 kg. The direct drive is designed to be operated constantly even at high temperatures (up to 80° C) and high relative humidity (up to 85%).

With the direct drive, the speed of the motor is the same as the speed of the vessels being shaken. There is no mechanical power transfer by friction wheels, no belt that can break down, or other mechanical wear and tear. The advantages include minimal noise, power consumption, heat transfer, and accurate speed display.

Advantages of Kuhner’s direct drive

The shaker table of an orbital shaker describes a circular motion with one revolution. The diameter of this circle is defined as the shaking diameter. Common shaking diameters are 0.5 inch (12.5 mm), 1 inch (25 mm) or 2 inches (50 mm).

The shaking diameter is a key factor for any cultivation process. At the same speed, larger shaking diameters allow for better oxygen transfer rate into the cultivation medium. This applies to both shake flasks and microtiter plates.

Use our Kuhner OTR Calculator to graphically understand how the shaking diameter influences the maximum oxygen transfer capacity and oxygen supply in shaken vessels.

For more information on the importance of the shaking diameter for shaken cultivations, please visit our Shaking Technology Forum: Why is the shaking diameter important?

Further details and scientific data on the correlation between maximum oxygen transfer rate, shaking frequency, and shaking diameter can be found in the Kuhner AppNote “Maximum oxygen transfer capacity in shake flasks” in the Kuhner Science Room.

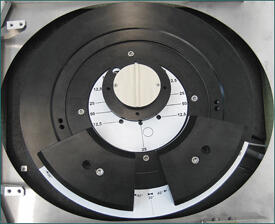

Kuhner’s direct drive system allows the user to change the shaking diameter at any time – quickly and easily. Our newest generation of flagship incubator shaker – the ISF1-Z – has eight fixed shaking diameters (3, 6, 9, 12.5, 19, 25, 50, 70 mm), and a stepless adjustment between 0 to 70 mm is now also a standard feature.

All other Kuhner shaking machines offer three standard shaking diameters: 12.5 mm, 25 mm, and 50 mm. On request, additional orbit diameters (e.g., 9 mm, 19 mm, or 70 mm) can be added, or they may be equipped with a stepless system for infinite adjustment from 0 to 50mm.

Maximum speeds are limited depending on the orbit diameter setting of the shaker to ensure a safe and smooth operation. Typical values are depicted in the table below (load capacity is also a factor), and the exact values for your Kuhner shaker can be retrieved from the respective manual:

Shaking diameter | Maximum shaking frequency |

|---|---|

3 mm | 800-1000 rpm* |

6 mm | 800 rpm* |

9 mm | 600 rpm* |

12.5 mm | 500 rpm |

19 mm | 400 rpm |

25 mm | 400 rpm |

50 mm | 300 rpm |

70 mm | 250 rpm |

*For 3, 6, and 9 mm shaking diameter, the

optional High-speed (HS) drive is required. | |

To integrate a robotic system for automated handling, it is critical that the shaking platform must always stop at the same position. Kuhner shakers have 48 stopping points that can be individually adjusted. This system is based on a magnetic lock-in and requires no maintenance.

The Kuhner Tray Positioning System (TPS) is available in two versions:

TPS: The drive can stop at any of 48 possible positions, which can be programmed on the MMI display or Kuhner Insight software. This feature is standard for our Kuhner direct drive system.

TPS+: Similar to TPS, but one of the 48 positions is an exact stop and has an alarm function in case anything is misaligned. This is important for automated/robotic applications. The TPS+ feature is optional and must be ordered additionally.

To speed up deceleration, an active brake is applied to the drive system when the ‘stop’ key is pressed or the door is opened.

The calibration procedure is automatic and can be completed within minutes. It requires only a serial interface and a computer with the Kuhner Insight software for calibration.

The direct drive uses a single eccentric bearing fitted to the top of the drive, so there is no internal stress between bearings. The user adjustable shaking diameter can be changed at any time by simply altering the position of the eccentric bearing.

The parallelogram ensures identical shaking movement anywhere on the tray, regardless of the load distribution. In addition, the double steel springs will last a lifetime.

The stator of the direct drive consists of DC electromagnets and sensors. The rotor is equipped with permanent magnets. The controller directly switches the electromagnets of the stator depending on the position of the rotor. As there are no brushes in this system, it is maintenance-free.

A microprocessor control achieves quartz precision speed regulation, and the speed remains constant irrespective of the load.

Speed accuracy: ± 0.5 rpm

Speed indication: ± 1.0 rpm, digital

Further Kuhner Technologies: