to view content for your location.

The Kuhner MPS-Z Automated was developed to automate cell culture cultivations in microtiter plates with or without system Duetz well plate closures. It combines the established Kuhner incubator shaker robustness with completely self-developed robotic features and interfaces. Main objective is to guarantee reproducible and uniform cultivation conditions and a real 24/7 work process.

The MPS-Z Automated incubator maintains Kuhner’s renowned features without compromise. CO₂, bi-directional humidity, and temperature control (heating and cooling with Peltier technology) adhere to the highest standards, ensuring reproducible cultivation results. The Kühner Direct Drive is known for its lack of wearable parts and long-term durability. Additionally, the built-in capability to change the shaking diameter (3, 12.5, 25, 50) enhances the system’s flexibility for the wide variety of microtiter used at different cultivation scales and volumes. Process safety is a high priority for Kühner devices. In addition to the mentioned key features, further safety measures have been implemented. The automatically secured door prevents unauthorized access to the incubator interior and initiates a complete inventory scan upon closing. Additionally, the occupancy sensors on the SCARA and at the transfer platform prevent potential collisions.

After a power interruption, the system restarts with the previous cultivation parameters. Furthermore, an integrated UPS system protects against data loss, and internal storage ensures data availability.

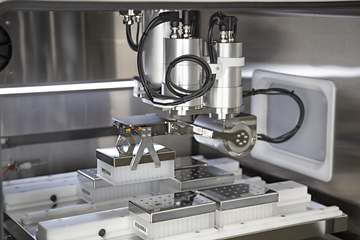

The Kuhner Hawk, our self-developed SCARA system (Selective Compliance Assembly Robot Arm System), purpose-designed to operate under particularly aggressive conditions (CO₂/humidity). The unique design and positioning within the system ensure minimal heat input and minimal impact on the temperature distribution in the incubator chamber. The flexibility of the Kuhner Hawk allows it to work with many different shaking diameters and a variety of deepwell plates. The compact gripper guarantee stable grip security while maintaining the MPS-Z Automated's 16 well plate capacity.

The large display mounted on the front door is designed to provide a quick overview of the process. All process parameters are clearly displayed, and the current work step is visualized. Additionally, the positions of the microtiter plates on the clamping table are shown. An acoustic and visual alarm management system is integrated.

To minimize the impact on cultivation parameters, the size and opening time of the side door have been optimized. Compared to opening the door of ISF1-Z, the side door opening on the MPS-Z Automated has negligible impact on control parameters within the chamber.

The side-mounted transfer platform includes both an optional barcode reader and occupancy sensor. The device offers high flexibility as the transfer platform can be preconfigured on both sides of the MPS-Z Automated chamber - meaning 'left' or 'right' orientation is possible to fit either orientation.

To prevent inconsistent cultivation results, Kuhner developed a new, patented, clamping table to ensure the firm fixing of microtiter plates during rapid shaking. Additionally, the quiet operation of the device and the secure clamping table minimizes abrasion of the microtiter plates, eliminating concerns about particulate generation in the chamber. The clamping table releases all plates upon stopping, allowing the Kuhner SCARA gripper (Kuhner Hawk) to easily pick up the microtiter plates.

One of Kuhner's development goals is the seamless and trouble-free integration of systems into automated platforms. This principle has also been applied to the MPS-Z Automated. The device features both a standard TCP/IP interface and a future-oriented SiLa2 (HTTP/2) interface. Additionally, numerous drivers are available for compatibility with integrator and liquid handler platforms right out of the box.

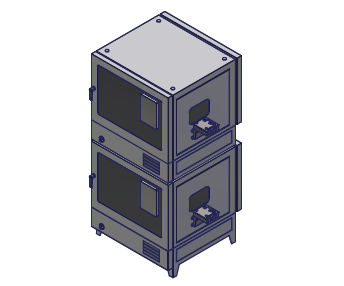

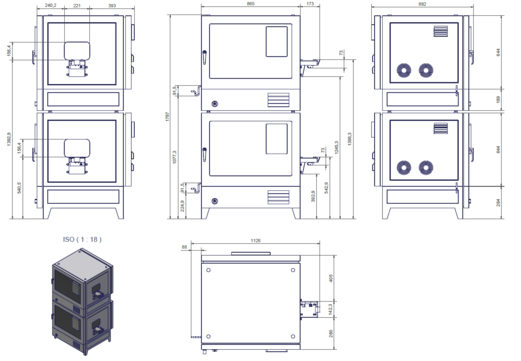

Maximize efficiency and optimize your lab with the ability to stack up to two MPS-Z Automated. This configuration is designed for seamless operation and offers high performance while saving space.

Shaking diameter

Dr. Shakers Helpful Hint N°4 explains what the shaking diameter is and how you can determine the shaking diameter of your lab shaker.

Find information on the importance of the shaking diameter for biological cultivations in our Shaking Technology Forum: Why is the shaking diameter important?

Unit | MPS-Z Automated | |

Cooling | yes / no | yes |

Temp. minimum | °C | min. 30 / if RT >25 °C: RT + 5 |

Temp. maximum | °C | 40 |

Setting, digital | °C | 0.1 |

Temperature distribution at 37°C/85% r.H. /25mm/400rpm | ± °C | ≤ 0.35 |

Power of heating (electric) | W | 125 |

Refrigerant |

| NA |

Power of cooling (electric) | W | 140 |

Principle of temp. sensor | type | Pt-100 |

Air recirculation | m3 / h | 373.4 |

Unit | MPS-Z Automated | |

Humidity max. at 30 - 40 °C | % r.H. | 85 |

Humidity min. at 30 - 40 °C | % r.H. | 70 |

Setting, digital | % r.H. | 1 |

Accuracy absolute | ± % r.H. | 2 |

Power of waterbath heater | W | 180 |

Power of door (front & back) and frame heater | W | 180 |

Water refill |

| automatic |

Principle of hum. sensor | type | capacitive |

Principle of hum. control | type | evaporation & recondensation |

Unit | MPS-Z Automated | |

CO2, max. | % | 20 |

CO2, min. | % | 0 |

Setting, digital | % | 0.1 |

Accuracy absolute | ± % | 0.40 at 5 % CO2 |

Temperature range | °C | up to 40 |

CO2 supply | bar | max. 2 bar overpressure |

Principle of sensor | type | Infrared |

Unit | MPS-Z Automated | |

Motor | Typ | direct drive |

Shaking diameter | mm | 3 - 50 mm, adjustable |

Shaking motion | Typ | orbital |

Shaking frequency range at 3 mm | U/min | 0, 20 - 1000 |

Shaking frequency range at 12.5 mm | U/min | 0, 20 - 500 |

Shaking frequency range at 25 mm | U/min | 0, 20 - 400 |

Shaking frequency range at 50 mm | U/min | 0, 20 - 300 |

Shaking frequency range at 70 mm | mm | not possible |

Loading max. | kg | 16 DWPs with Duetz & Clamp (10 kg) |

Setting, digital | U/min | 1 |

Accuracy absolute | ± U/min |

20

- 800 rpm = 0.5 |

Acceleration | s:h | automatic |

Active brake |

| automatic |

TPS+ |

| yes, automatic |

Power of standard motor (EM-Z HS) |

| ja |

Unit | MPS-Z Automated | |

Power consumption typical (steady state) | W | approx. 280 |

Power consumption typical (startup heating, humidity, etc.) | W | approx. 605 |

Power consumption max. (type plate) | W | 1000 |

Power cable length | mm | 300 mm (CH & AU: 250 mm) |

Incubation gas volume | L | 230 |

Weight | kg | 260 - 270 |

Illumination | type | LED |

Interface, standard | Ethernet TCP / IP, | |

Parent / child | Always Child | |

Ambient temperature | °C | 10 - 35 |

Cable feedthrough port (side port) | mm | 40 |

Dimensions (L x D x H) | mm | 1107.5 x 892.5 x 984 |

Sound Level @1000 rpm | dB | < 59 |

Compatible MTPs type |

| DWP 96/48/24/12/6 |

Unit | MPS-Z Automated | |

Sample rate recording | seconds | Every 5 second, 3 month recorded |

Connection | TCP sockets/ SiLA 2 | |

Command response | Response in JSON format | |

Manual door open request time |

seconds | 30 sec |

Emergency stop | yes | |

Barcode reader (code types…) long or short side | optional | |

Static nest (maximum size) | ANSI Format +- LBT | |

Robotic system | 4 Axis SCARA | |

Dimension and position of external transfer platform | Position in relation to the machine defined by drawing. Height adjustable by optional floor stand | |

Transfer platform direction | Right / Left | |

Technical data subject to change | ||

Technical data subject to change

CO2 control is essential when working with mammalian cell cultures. Kuhner was the first company to manufacture and supply incubator shakers with CO2 control more than 15 years ago and continues to offer this optionCustomize your MPS-Z Automated experience with the MPS-Z(C) option. More

The barcode reader, optionally integrated into the transfer platform, contributes to process security. The flexibly mountable reader can read barcodes either on the long side or the short side of the microtiter plates.

The patented Nemiri clamps enable the automated use of system Duetz well plate closures Automated clamping and de-clamping is accomplished using the optional, stand-alone, Kuhner Nemiri clamping system.

The floor stand is characterized by its flexible height adjustment (position of the transfer platform 1110 mm ± 40 mm) and the lockable storage space.

The following flyers provide information about the machines and function-specific solutions.

Watch the following video and learn why the MPS-Z Automated is the perfect fit for automated processes.

At Kuhner Shaker, we believe that innovation happens when great minds come together. Together with our partner LABServices, we have developed a next-generation demo system that pushes the boundaries of what’s possible in bioprocessing.

By combining the PlateButler, MPS-Z Automated, ISF1-Z Beluga, and the brand-new Nemiri, this system demonstrates how easy it can be to automate reliable and precise culturing, from microplates to larger TPP bioreactors.

Kuhner shakers are suitable for the cultivation of microbial, plant, human and animal cell cultures. Find more information about the different application areas and suitable product recommendations for optimal cultivation here.

Adolf Kühner AG (Headquarters)

Dinkelbergstrasse 1

CH-4127 Birsfelden (Basel)

Switzerland

We support our customers in implementation, maintenance and repair of all Kuhner products – efficiently and competently.

For Kuhner, the quality and durability of their shakers and bioreactors have always been the topics with the highest priority. On this account, Kuhner products have also proven their worth worldwide under GMP requirements. Documentation, development and production along the full life cycle of our products are continuously enhanced to match the requirements of 21 CFR and GAMP 5.

Read more

The world's most reliable shaking machines built in-house in Switzerland.