to view content for your location.

Does our existing range of products not meet your requirements? Do not hesitate to get in touch with us. We would love to hear more about your distinct application. Tailor-made solutions are our business. We will work with you to create an optimal solution for your shaking machine or shaken bioreactor system (OSB).

Do you have an unconventional or unique shaking vessel? Send us a prototype of your vessel and we will develop a suitable clamp. Would you prefer to combine your measuring system with one of our shakers? Do you require a shaking machine with an unconventional feature? We can adapt our shakers to fit your needs.

Each of our customized solutions is specifically adapted to the user's request. Our Kuhner Atelier team provides the expertise and advice to find the optimal solution for each customer and will happily address any questions or technical issues.

If you have any questions regarding our customized solutions or products in general, please contact us: atelier@kuhner.com

GMP production processes often are subject to rigorous safety and process regulations requiring redundant external temperature, humidity, or CO2 monitoring in incubator shakers. To address such requirements, our Kuhner Atelier department has developed a customized solution which incorporates additional sensors monitored by the user's process software.

On the pictures you see an example of a customized solution for redundant temperature monitoring in the ISF1-Z incubator shaker: several magnetic holders are implemented for additional temperature sensors at different locations in the system.

The ISF1-Z Basic Beluga – once a customized project, now one of our regular products – was specifically designed for automation and robotic systems. The lowered shaking platform gives more interior headspace, allowing for a robotic arm to reach into the chamber and grab any vessel from the shaking tray. The ISF1-Z Basic Beluga can be integrated into many areas of automation, such as screening for an optimal cell line, media development, or analytical applications.

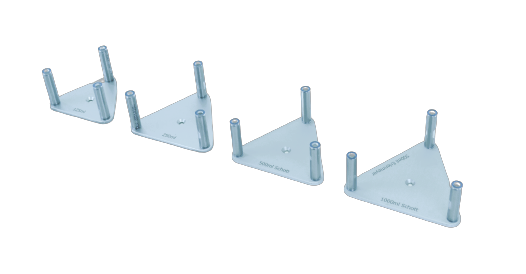

The pin-clamps are ideal for cleanrooms and areas where sticky mats or other standard clamps are unsuitable. The clamps have been designed for easy cleaning and efficient handling of samples. Made of stainless-steel pins and aluminum bottom plates, they are compatible with all Kuhner universal trays. A replaceable rubber cover prevents the bottles from rotating in the clamp. The shaking speed is limited to 180 rpm at 50 mm shaking diameter. The pin-clamps are available for 125 mL, 250 mL, and 500 mL Erlenmeyer flasks, as well as 500 mL and 1000 mL Schott laboratory bottles.

Do you perform biological cultivations in a comparatively large-sized, a custom-made, or an unconventional shaking vessel? And would you like to obtain online monitoring data to gain a better understanding of your bioprocess?

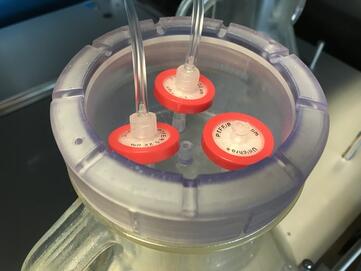

Kuhner offers customized caps to connect all types and sizes of shaken cultivation vessels to the Kuhner TOM online monitoring system. This enables the customer to monitor online respiration and metabolic activity of microbial and cell cultures in these vessels as well.

For instance, Kuhner has designed a customized Kuhner TOM cap for Thomson Optimum Growth Flasks which are routinely used for cell culture processes. This Kuhner TOM cap works for the 1.6 L, 2.8 L, and 5 L Thomson flasks. The three ports of the cap are for gas inlet, outlet to the sensors, and pressure equilibration (port without tube). The Thomson-Cap is reusable by autoclaving at temperatures up to 121°C without losing its mechanical performance.

Send us a sample of the container that needs to be shaken.

We will build a suitable holder.

Custom-made accessories, an everyday occurance for us.