to view content for your location.

Freezing of many vials in a freeze dryer normally works out as a stochastic process. All vials will freeze only within a certain time frame, e.g. 1 hour. Furthermore, this crystallisation happens at different temperatures. Crystal structure and later drying behaviour will diverge.

For futher information:

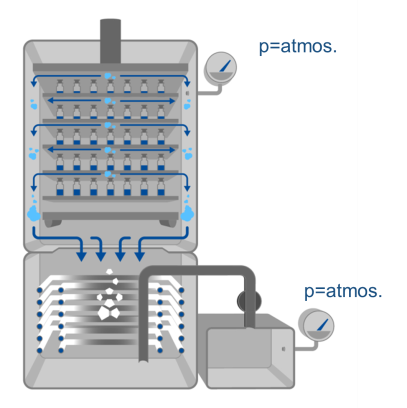

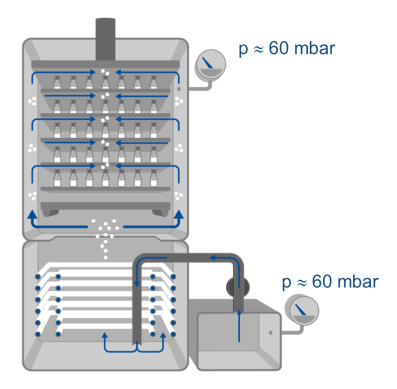

The new developed technology LyoCoN (Controlled Nucleation) creates a controlled nucleation of all to be lyophilised vials. After loading of the freeze dryer, the cold ice condenser accumulates ice crystals (Fig. 1). Simultaneously the liquid product is cooled down close to the freezing point. In the next step a slight vacuum is established in the freeze dryer (Fig. 2). The external recipient is kept under atmospheric pressure. Finally a pressure equilibration between recipient and freeze dryer is started by opening a valve to the ice condenser. The air/gas from the recipient is injected into the ice condenser. The resulting ice fog infiltrates all vials (Fig. 3). These crystal nuclei immediately start homogeneous crystallisation in all vials.

After this, the freeze dryer is aerated completely to atmospheric pressure. Freezing of all crystallized vials can be continued in a conventional way, e.g. by further cooling down, annealing etc.

Figure 1: Ice crystal accumulation at ice condenser.

Figure 2: Formation of a slight vacuum in the freeze dryer.

Figure 3: Injection of an ice fog in the product chamber by pressure compensation between external recipient and ice condenser chamber.

Mr. Jörg Kellerhals

Sales Manager

Basel, Bern, Luzern and Ticino

Mrs. Véronique Miano

Sales representative Western Switzerland

Mrs. Valeria Farsaci

Sales representative Eastern Switzerland

We support our customers in implementation, maintenance and repair of all Kuhner products – efficiently and competently

Email: service@kuhner.com