to view content for your location.

The Kuhner TOM (Transfer-Rate Online Measurement) provides online measurements of the oxygen transfer rate (OTR), carbon dioxide transfer rate (CTR), and respiratory quotient (RQ) for up to 16 individual shake flasks in a Kuhner incubator. The TOM provides the user with a better understanding of any bioprocess and allows for more efficient and effective optimization during process development. It is easily installed in any Kuhner shaker and is compatible with a variety of different shake flask types and sizes, including single use shake flasks.

Online Measurement

Flexibility

Application

Retrofittable

The modularity of the Kuhner TOM allows the user to choose online measurements from 4, 8, 12, or 16 shake flasks. The TOM itself is mounted above the shake flasks and requires no space on the shaking platform, maximizing the capacity for shake flasks in the incubator.

The Kuhner TOM captures the progress of multiple cultivations over time, providing an opportunity for the user to selectively schedule off-line sampling and analysis at critical time points. The TOM offers valuable insight on the viability and growth rate of shaken cultivations and will also help identify sub-optimal conditions, including oxygen limitation, substrate limitation, or product inhibition. The TOM also provides an opportunity for the systematic and rapid optimization of culture media and conditions (e.g. balancing different carbon sources or media additives, substrate uptake and product formation via RQ). The OTR, CTR, and RQ data captured from the TOM will accelerate any process development and facilitates scale-up.

Temperature range | 15-40°C |

Shaking speed | < 600 rpm |

Orbital shaking diameter | 3 mm – 70 mm |

Flask size |

250 mL – 1000 mL (smaller and larger

flasks on request) |

Filling volume | > 4% of nominal flask volume |

Humidity | < 85% rel. humidity |

Concentration range | CO2 < 16% |

Maintenance | CO2 sensor calibration once per month Pump adjustment after 1 year |

Warranty time | 2 years |

Technical data subject to change | |

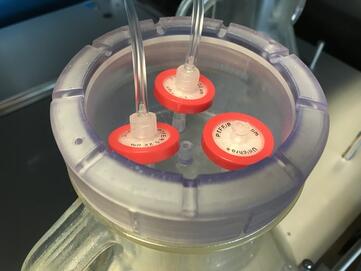

The Kuhner FlexCap is a universal silicone adapter lid that enables the utilization of various sizes and forms of shake flasks in the Kuhner TOM system to measure the oxygen and carbon dioxide transfer rates. Its specific construction seals both the smaller and more narrow flasks (min. 25 mm inner diameter) and the larger and wider flasks (max. 55 mm outer diameter), respectively, using the same universal lid. With the FlexCap, also cultivations in custom-made flasks and baffled shake flasks are now accessible for online measurements with the Kuhner TOM system.

In addition, the FlexCap can also be used for aeration of shake flask cultivations with FlowCon and Kuhner AerationSystem (consisting of FlexCaps and GasDivider). This enables users to run cell cultivations in a non-humidified and non-O2/CO2-controlled environment. The FlowCon provides a precise gas composition and flow rate, while the GasDivider humidifies and distributes the gas flow evenly to the inlet ports of the FlexCaps.

Besides the ports for air inlet and outlet, the FlexCap comes with an extra port for external feeding and sampling. Best of all, the FlexCap is reusable by autoclaving at temperatures up to 121°C without losing its mechanical performance.

Do you perform biological cultivations in a comparatively large-sized, a custom-made, or an unconventional shaking vessel? And would you like to obtain online monitoring data to gain a better understanding of your bioprocess?

Kuhner offers customized caps to connect all types and sizes of shaken cultivation vessels to the Kuhner TOM online monitoring system. This enables the customer to monitor online respiration and metabolic activity of microbial and cell cultures in these vessels as well.

For instance, Kuhner has designed a customized Kuhner TOM cap for Thomson Optimum Growth Flasks which are routinely used for cell culture processes. This special cap works for the 1.6 L, 2.8 L, and 5 L Thomson flasks. The three ports of the cap are for gas inlet, outlet to the sensors, and pressure equilibration (port without tube). The Thomson-Cap is reusable by autoclaving at temperatures up to 121°C without losing its mechanical performance.

If you are interested in the Thomson-Cap or in a customized cap for your own cultivation vessel, please contact us: office@kuhner.com

Cultivation of entomopathogenic fungi in orbitally shaken bioreactors

Kuhner TOM for off-gas analysis in shake flasks

TOM system for analyzing the respiratory activity of a CHO cell pool expressing SARS-CoV-2 Spike Protein

TOM system for analyzing the respiratory activity of a CHO cell pool expressing SARS-CoV-2 Spike Protein in a Fed-Batch process

Examining the respiratory activity of CHO cell pool expressing SARS-CoV-2 spike protein across shake flask scales using the TOM system

Off-gas analysis of Komagataella phaffii on different carbon sources

Impact of protein production on metabolic activity of CHO stable cell line producing palivizumab

In our Science Room, we offer general information and data of cultivation processes in shaken bioreactors.

Kuhner TOM - Transfer-Rate Online Measurement

The Kuhner TOM (Transfer-Rate Online Measurement) provides online measurements of the oxygen transfer rate (OTR), carbon dioxide transfer rate (CTR), and respiratory quotient (RQ) for up to 16 individual shake flasks in a Kuhner incubator. The Kuhner TOM provides the user with a better understanding of any bioprocess and allows for more efficient and effective optimization during process development. It is easily installed in any Kuhner shaker and is compatible with a variety of different shake flask types and sizes, including single use shake flasks.

The following flyers provide information about the machines and function-specific solutions.

Kuhner shakers are suitable for the cultivation of microbial, plant, human and animal cell cultures. Find more information about the different application areas and suitable product recommendations for optimal cultivation here.

Adolf Kühner AG (Headquarters)

Dinkelbergstrasse 1

CH-4127 Birsfelden (Basel)

Switzerland

We support our customers in implementation, maintenance and repair of all Kuhner products – efficiently and competently.

For Kuhner, the quality and durability of their shakers and bioreactors have always been the topics with the highest priority. On this account, Kuhner products have also proven their worth worldwide under GMP requirements. Documentation, development and production along the full life cycle of our products are continuously enhanced to match the requirements of 21 CFR and GAMP 5.

Read more

The world's most reliable shaking machines built in-house in Switzerland.